Effective Strategies for Heat Safety in School Maintenance Staff

Blogs

According to the Occupational Safety and Health Administration (OSHA), 50-70% of outdoor fatalities occur in the first few days of working in warm or hot environments because people need to build a tolerance to heat gradually, over time.

Inevitably, some of your district employees must work in a hot environment — be it while mowing, trimming, lining athletic fields, painting, roofing, performing electrical work, repairing buses, coaching athletics, or even working in indoor boiler rooms. In this blog we’ll explore the types of exertional heat illness your staff is susceptible to, legal requirements for heat safety, risk factors, as well as six effective strategies for preventing heat-related illnesses in school maintenance staff.

Types of Exertional Heat Illness

When the temperature of your body rises, it perspires. As this sweat evaporates from your skin, your body cools. Anything that interrupts this process causes your internal body temperature to rise. A body-temperature increase of only 2°F (1.1°C) can affect mental functioning; a 5°F (2.8°C) increase can result in serious illness or death.

Exertional heat illness (EHI or heat illness) includes a spectrum of disorders caused by environmental heat exposure. In increasing order of severity, they are:

- Heat rash

- Heat cramps

- Heat syncope

- Heat exhaustion

- Heat stroke

Legal Requirements for Heat Safety in School Maintenance Staff

When it comes to heat safety in school maintenance staff, it’s important to understand the legal requirements that govern workplace safety. Below we explore the different regulatory frameworks for heat safety, specifically focusing on which states adhere to the federal Occupational Safety and Health Administration (OSHA) guidelines and which states have their own OSHA-approved plans. By knowing these distinctions, district superintendents can ensure compliance and create a safe working environment for their maintenance staff during hot weather conditions.

National and State-Specific Heat Standards

Click here for the National Institute for Occupational Safety and Health’s standard for occupational heat stress.

- Alabama

- Arkansas

- Colorado

- Delaware

- District of Columbia

- Florida

- Georgia

- Idaho

- Kansas

- Louisiana

- Mississippi

- Missouri

- Montana

- Nebraska

- New Hampshire

- North Dakota

- Ohio

- Oklahoma

- Pennsylvania

- Rhode Island

- South Dakota

- Texas

- West Virginia

- Wisconsin

Four Risk Factors that Increase the Likelihood for Heat Illness in School Maintenance Staff

Understanding the risk factors heat illness in school maintenance staff is crucial for prevention and protection. Let’s examine four key risk factors – environmental, personal, workload, and PPE – that can increase the likelihood of heat illness among maintenance workers.

1. Environmental Risk Factors

Increasing the likelihood of heat illness are environmental risk factors, such as:

- External sources of warmth, including air temperature, radiant heat, and conductive heat sources

- Relative humidity and air movement, which impact how effectively you can cool via sweat evaporation

2. Personal Risk Factors

Personal risk factors that impact someone’s ability to stay hydrated, react to heat and respond to workload include:

- Certain health conditions, like cystic fibrosis, diabetes, gastro-intestinal distress, heart issues, kidney problems, hyperthyroidism, obesity, pregnancy and sickle-cell trait.

- Salt tablets and certain medications, such as antihistamines, blood-pressure pills, diuretics, Dopamine-reuptake inhibitors (e.g., Ritalin®), non-steroidal anti-inflammatory drugs (e.g., ibuprofen, aspirin and naproxen) and some tranquilizers.

- Consumption of alcohol or drugs within 24 hours of work and/or consumption of energy drinks.

- Dehydration, fatigue and/or a lack of heat acclimation.

- Lack of physical fitness and/or not being used to being physically active in the heat.

- Sunburn and/or a previous heat-related illness.

3. Workload Intensity and Duration

Workload intensity and duration is yet another risk factor. Consider the physical effort required to perform various tasks in 60°F (15.6°C) versus 90°F (32.2°C) weather. Workloads can be grouped into three categories: moderate exertion, heavy exertion, and very heavy exertion.

4. Personal Protective Equipment

Just as a job’s heat burden increases as the temperature rises, so too does it increase when necessary personal protective equipment (PPE) is worn. In fact, employees can develop heat illness during mild, temperate weather, if they’re wearing heavy PPE while performing physically challenging tasks.

Six Strategies for Preventing Heat Illness

Most people’s limit of high-temperature tolerance is 95-104°F (35-40°C). Below we explore six different strategies for preventing heat-related illnesses in school maintenance staff.

1. Provide Heat Illness Training

Implementing comprehensive heat illness training programs is crucial to equip school maintenance staff with the knowledge and skills needed to recognize and prevent heat-related risks. Through training sessions focused on heat illness awareness and heat illness prevention, maintenance staff can be empowered to take proactive measures to protect themselves and their colleagues from heat-related hazards. Regular refresher courses and ongoing education can ensure that staff members stay updated on the latest best practices for heat safety in the school environment.

Automate Your Heat Illness Training

2. Monitor the Weather

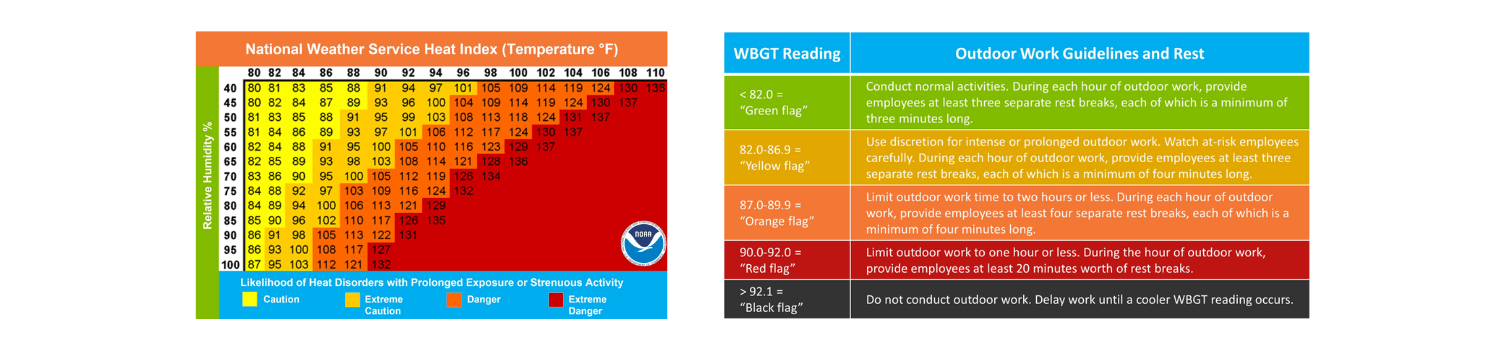

There are two effective ways to monitor the weather to ensure heat safety for maintenance workers in schools: heat index and wet-bulb glove temperature (WBGT). We recommend considering both the WBGT and the heat index when determining whether to modify, adapt or cancel outdoor work.

1. Heat Index Method: The heat index indicates how hot it feels by considering both the temperature and the humidity. To determine the heat index, you can use a free, downloadable smartphone app called Heat Safety Tool or measure air temperature and humidity, then utilize the National Weather Service Heat Index chart

To measure the air temperature at a worksite, all you need is an ordinary outdoor thermometer. Measure the temperature in an unshaded area and use your hand to shield the bulb from sunlight. In addition, measure the air temperature away from sidewalks, blacktops, cars, and other surfaces that absorb or reflect heat.

Humidity is the measure of moisture in the air. Sweat does not evaporate as quickly in high humidity, which makes it harder for someone to cool off. Irrigation systems that run before employees or coaches work outdoors can create humidity that lasts until the water completely soaks into the ground or evaporates.

2. WBGT Method: WBGT is a measure of environmental heat stress based on air temperature, humidity, wind, and radiant energy from the sun. OSHA and numerous school-sanctioned athletic programs monitor WBGT to prevent heat illness. Many companies produce devices that calculate WBGT. When using one of these devices, take the reading 10-15 minutes before beginning outdoor activities. Consider both the WBGT and the heat index when determining whether to modify, adapt or cancel outdoor work.

3. Acclimate Employees to Heat and Modify Their Workload

Employees not used to working in heat are more likely to develop a heat-related illness. This includes:

- New workers.

- Workers returning from an absence of two weeks or longer.

- Staff who switch from working indoors to outdoors.

- All employees when there is a large temperature jump from one day to the next.

For these workers, special precautions are needed. Acclimation (i.e., acclimatization) is the process by which the body adjusts to increased heat exposure. Most people can acclimate within 10-14 days, providing they perform two hours of regular work, in the heat, daily, during that time. Proper acclimation becomes even more important for work that requires intense physical exertion.

A supervisor or designee should closely observe employees who are new to high-heat conditions during their first two weeks on-the-job. And during a heat wave, a supervisor should closely monitor all employees for symptoms of heat illness.

4. Make Sure Employees Stay Properly Hydrated

In a day, it’s normal for the human body to sweat as much as a quart (.9 liters) of fluid. And a hard-working adult can perspire 16 times that amount. After only a few hours, dehydration can cause shock and even death.

Energy drinks can actually increase the risk for heat illness. Sports drinks are an excellent source of carbohydrates and electrolytes and are recommended when physical activity lasts more than one hour. However, for physical activity that lasts less than an hour, they’re no more effective than water for hydration.

Many people don’t recognize when their bodies need water. It’s better to ingest frequent drinks of water than it is to drink large amounts of water only when thirsty, or only during rest periods. An employee hydration program should include strategies for daily hydration, as well as for hydration before, during and after work.

Daily Hydration

•Urge employees to drink plenty of water — one quart (one liter) per hour — when not at work.

•Encourage employees to include produce, which primarily comprises water, in their diet.

•Advise employees that urine color is an easy way for them to self-monitor hydration levels. Light-colored urine indicates adequate hydration.

Pre-Work Hydration

•Encourage employees to drink 16-24 fluid ounces of water (400-700 ml) within four hours of outdoor work.

•Ask employees to drink an additional 8-16 fluid ounces (200-500 ml) 15 minutes prior to outdoor work. Explain that consuming a beverage with sodium and/or eating a small, salty snack will help stimulate their thirst and retain fluids.

During-Work Hydration

•Supply employees unlimited access to water.

•Allow employees to wear water-bladder backpacks or belts that hold water bottles, if they don’t interfere with the outdoor work.

•Remind employees to consume at least 8 fluid ounces (200 ml) of fluid every 15 minutes during outdoor work.

•If employees are active for longer than an hour, have them consume some carbohydrates (e.g., sports drinks), which positively impact performance and cognitive function.

Post-Work Rehydration

•Ask employees to consume most of the water they lost while working outdoors within two hours of the work’s completion, and to replace the rest within six hours.

•Encourage employees to consume sodium during post-activity recovery; however, advise against salt tablets, which concentrate sodium in the stomach.

5. Provide Employees the Chance to Rest in the Shade

Resting in the shade reduces heat stress, as shade blocks sunlight as a direct source of heat. Direct sunlight can make the air feel 10-15°F (5.6-8.3°C) warmer than it is.

That said, shade is by no means a cure-all. Shade isn’t as helpful for cooling when humidity levels are high. Furthermore, shaded areas near blacktopped parking lots — as well as unventilated outbuildings — may have higher air temperatures than an unshaded grassy field.

6. Plan for Emergencies

Even after following all the strategies above, it’s best to be prepared for an emergency. You should have district policies for when and how to monitor an employee with heat-illness, as well as instructions for when emergency services should be called.

More than 20% of heat-stroke victims die. In an emergency it’s critical you provide first-aid and call 911 immediately.

When monitoring an employee for heat-illness symptoms:

- Escort the employee to a shaded area, and immediately determine their pulse by counting their number of heart beats per minute. After the employee has rested a few minutes, re-take their pulse, which should now be lower. A pulse rate that remains elevated is an indicator of a heat-related illness.

- Measure the employee’s breathing rate, by counting their breaths per minute. Like their heart rate, their breathing rate should decrease with rest. A breathing rate that does not quickly return to normal is an indicator of heat-related illness.

- Continually talk to the employee to assess whether they’re conscious, alert or confused. Even after an employee’s heat-illness symptoms have disappeared and they’ve returned to work, they should still be checked periodically.

An employee with severe symptoms of heat exhaustion needs to cool off by any means possible. Do one or more of the following:

- Move the employee to a cool place. Have them lie down with their legs straight and elevated 8-12 inches (20.3-30.5 cm), to prevent shock. If the worker feels nauseated, roll them onto their side.

- If the worker is conscious, provide them with cool water to drink.

- Remove the employee’s PPE and protective clothing. Lightweight clothing should be loosened but can remain in place.

- Fan the victim.

- Place ice packs, cold packs or wet cloths on parts of the worker’s body where there is significant blood supply (e.g., their neck, armpits and groin). If you’re using cloths, continuously drench them with cool water.

- Do not administer aspirin or acetaminophen.

Implementing effective strategies for heat safety in school maintenance staff is essential to prevent heat-related illnesses and ensure a safe working environment. By understanding the types of exertional heat illness and complying with legal requirements set by either Federal OSHA or State OSHA-approved plans, districts can establish a solid foundation for heat safety protocols. Additionally, recognizing the four risk factors that contribute to heat illness—environmental, personal, workload, and lack of proper personal protective equipment—allows districts to address specific challenges. By implementing the six strategies outlined in this blog—providing training, monitoring weather conditions, acclimating to heat, ensuring proper hydration, providing adequate breaks, and having emergency plans in place—districts can effectively prevent heat-related incidents and protect the well-being of maintenance staff. Remember, a proactive approach to heat safety is key to creating a healthy and productive work environment.

1. Make sure your district has a Heat-Illness Prevention Plan. If you’re a PublicSchoolWORKS (PSW) customer, visit our online Safety Document Library. Under “Program Plans & Policies” tab is a sample plan that you can use as-is or that you can customize.

2. Train your maintenance staff how to stay safe in the heat. If you’re a PSW client, contact your client-services representative. Have them enroll your maintenance-staff members in our “Heat-Illness Awareness” course, and have them enroll your maintenance supervisors in “Heat-Illness Prevention.” Likewise, have your rep enroll all maintenance personnel in applicable PPE and first-aid courses.

3. Remind your maintenance-staff supervisors to discuss heat-safety guidelines at their next safety-committee meeting. If you’re a PSW customer, ask your PSW client-services rep to set up a compliance task; the task will automatically remind supervisors on your behalf.

4. Remind your maintenance-staff employees how to report any potentially dangerous heat hazards, as well as any incidents of heat illness. If you’re a PSW client, our “Hazard & Near-Miss Reporting” system and our “Staff Accident Management” system will streamline both processes for them, and for you.